Things about Inventory Management

Wiki Article

The 7-Minute Rule for Inventory Management

Table of ContentsInventory Management - The FactsThe 10-Minute Rule for Inventory ManagementNot known Details About Inventory Management Not known Details About Inventory Management

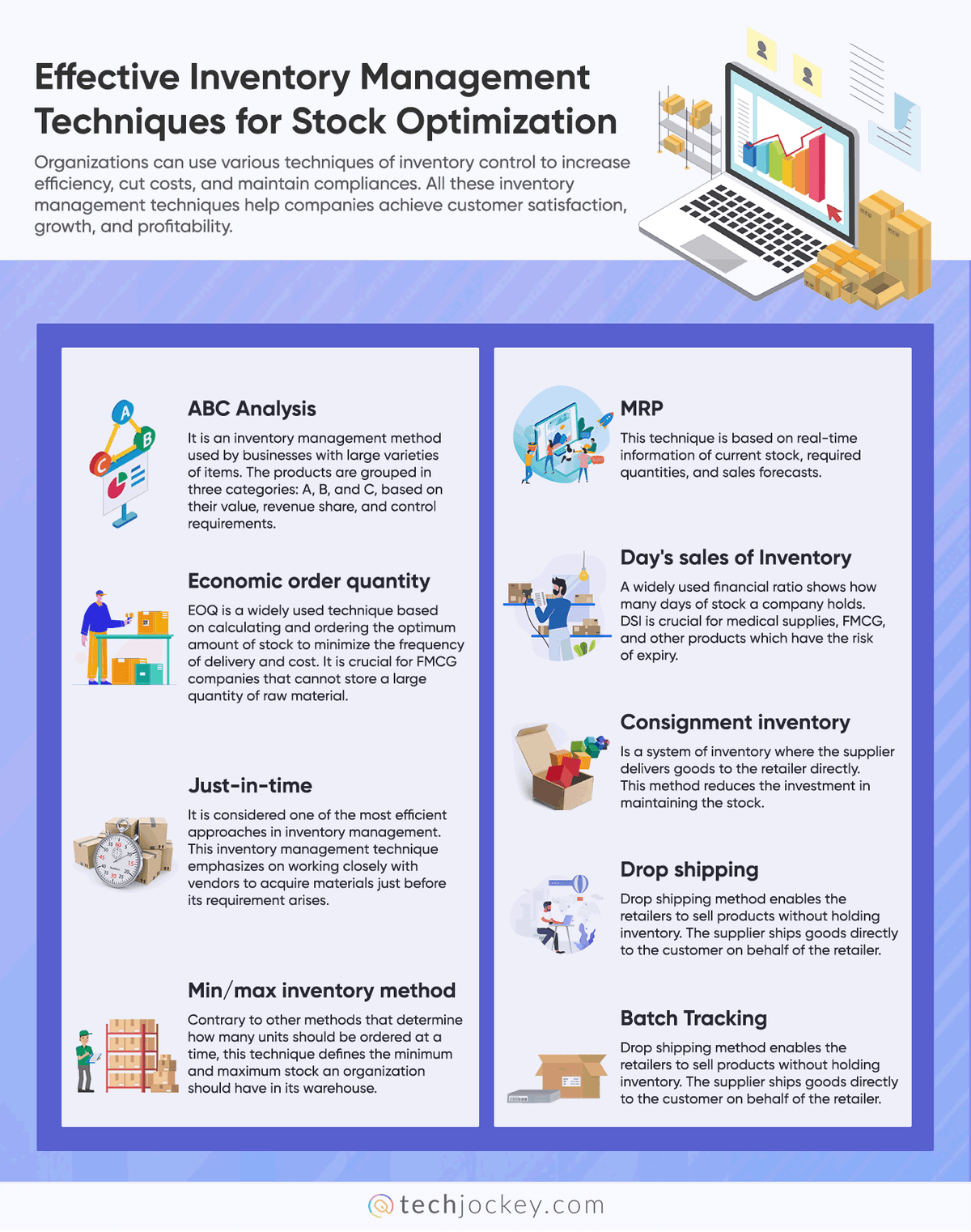

There are 2 major methods of maintaining track of supply: regular as well as continuous. The main difference in between these is how usually data is updated. Regardless of exactly how usually you track inventory, you may wish to utilize one of the adhering to supply monitoring methods: ABC Evaluation, ABC (Always Better Control) Analysis is stock management that separates different things into three categories based upon prices and is separated into teams A, B, or C.EOQ Model, Economic Order Amount is a method utilized for planning and also getting an order quantity. It entails making a choice pertaining to the quantity of stock that need to be placed in supply at any given time.

FSN Technique, This technique of supply control refers to the procedure of monitoring all the products of supply that are not made use of frequently or are not called for regularly. They are after that categorized into three various categories: fast-moving supply, slow-moving inventory, and also non-moving supply. JIT Technique, In the nick of time stock control is a procedure utilized by manufacturers to control their supply levels.

Inventory Management Fundamentals Explained

VED Analysis, VED is a method used by companies to manage their stock. The high degree of supply that is required for manufacturing generally justifies the low inventory for those parts.Wrike's item launch automation helps accelerate product launches with a structured strategy.

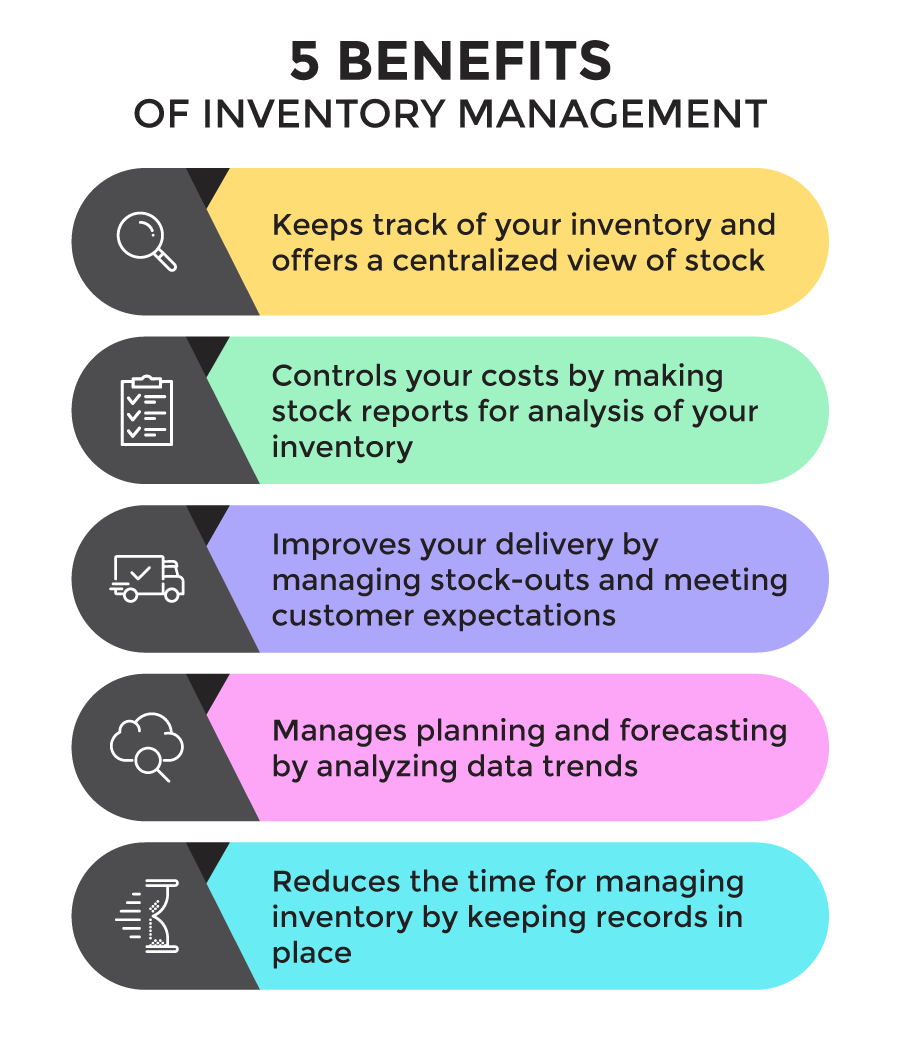

Supply monitoring tries to effectively improve inventories to avoid both gluts and scarcities. Four major stock monitoring methods consist of just-in-time administration (JIT), materials requirement preparation (MRP), economic order amount (EOQ), as well as days sales of supply (DSI).

A lack of inventory when and where it's required can be incredibly harmful (Inventory Management). Full Report At the same time, inventory can be considered a responsibility (if not in a bookkeeping feeling). A huge check my blog supply lugs the risk of wasting, burglary, damage, or shifts in demand. Supply must be guaranteed, and also if it is not marketed in time it might have to be thrown away at clearance pricesor just destroyed.

Tiny businesses will often maintain track of stock by hand as well as establish the reorder factors as well as quantities making use of spread sheet (Excel) solutions.

The 10-Minute Rule for Inventory Management

Ideal supply administration strategies vary relying on the industry. An oil depot is able to save large amounts of supply for extended time periods, enabling it to wait for demand to select up. While keeping oil is expensive as well as riskya fire in the U.K. in 2005 caused millions of extra pounds in damage and finesthere is no danger that the supply will spoil or head out of style.For business with complex supply chains and also producing procedures, stabilizing the threats of inventory excess and also lacks is particularly difficult. To achieve these balances, companies have established several approaches for supply management, including just-in-time (JIT) and products demand planning (MRP). Some companies, such as financial solutions companies, do not have physical stock therefore must count on solution process management.

Inventory has to be literally counted or measured prior to it can be put on an equilibrium sheet. Completed goods are completed items readily offered for sale to a company's consumers. Depending on the type of service try this out or product being evaluated, a company will make use of numerous supply administration approaches.

Report this wiki page